PDM, or Product Data Management, is all about how companies handle and organize their product information using methods and tools. It is a way organizations control and arrange details about their products, making sure everything is in order and well-organized. Read on to know more about it.

This blog post will discuss PDM and the 10 top PDM software programs available. Stay tuned!

Product Data Management Definition (PDM definition)

Product Data Management (PDM) is the collection of the organization’s product data and maintenance. This data can include anything fromengineering drawings and BOMs to marketing materials and customer support information.

The below image represents product data management in detail.

PDM’s purpose is to ensure that all this data is accessible to everyone who needs it, whether in engineering, manufacturing, or marketing.

As a result, companies can avoid duplication of work, ensure consistency across different product versions, and make it easier to bring new products to market quickly and efficiently.

Now let us look into PDM in detail.

Overview

PDM system is specifically designed to store and manage the complete information in a more robust and retrievable manner, including computer-aided design (CAD) data, models, parts information, manufacturing instructions, requirements, notes, documents, etc.

Product data includes any information related to the characteristics of a product and technical specifications such as its size, price, color, materials used, usage instructions, and more.

This data is essential for businesses as it provides valuable insight into customer demand and can help them create more effective marketing strategies.

Product data also helps businesses understand their competitors better, as they can compare their product offerings against those of their competitors to identify areas where they can gain a competitive advantage.

Additionally, product data allows companies to track inventory levels to ensure that they remain adequately stocked.

Regarding the engineering side, the specification includes manufacturing instructions and CAD models.

Following are the data managed by PDM.

- Brand name

- Part number

- Description of product

- Vendor information

- Vendor part number

- Unit of measurement

- Product specification

- Bill of materials

- Cost of the product

- CAD drawing

- Material and Part datasheets

If a Product Data Management System can address all the requirements of an organization and is accessible by multiple applications across an organization, it would be considered an ideal PDM system.

Choosing the right PDM software can allow the company to survive in the excessively saturated market.

It stores all the information about the products in an organized, less vulnerable, and retrievable manner.

All the other systems can then leverage the information stored in the PDM system within the company that needs information about the specific product.

This information may include extensive information about the particular product ranging from the raw materials deployed in the manufacturing cycle to how it was manufactured.

The data feed by the PDM system behaves as a source for various business functions, from design to manufacturing.

Ensure the Highest Level of Security

PDM systems store and manage sensitive information about a specific product in a way more secure and manageable form and ensure that all users can appropriately leverage this information throughout the product development lifecycle.

PDM system ensures the highest level of administrative functionality and security features through the proper implementation of role management, project-based security, and access privileges.

The merger of the Bill of Materials BOM data

Product Data Management necessitates the management of BOM data.

The automated system of PDM facilitates the synchronization of BOM data emerging from the different sources and product development lifecycle phases that include as-designed, as-planned, as-managed, and as-maintained states.

PDM system offers the highest level of customization of all the core functionalities, allowing you to perceive BOM data before and after the modifications.

Live demonstration of the product development lifecycle encompasses sharing and on-demand visualization of the product and under-the-hood product assemblies and parts without relying on any Cad authoring tool or technical knowledge.

Digital mockup features can reduce the cost incurred on physical prototyping.

Data Management Process

Data management is crucial for all businesses for their overall growth. So while implementing this process, you need to follow the below steps.

1. Decide data architecture

Every work needs a blueprint. The determination of data architecture serves as a blueprint that determines all the databases and software you require for your organization’s data management process.So it is essential to decide where you want to store your data.

2. Allot responsibilities

While implementing the data management process, ensure who is responsible for which work. Then, assign the work to each person.Opacity in the team leads to poor data quality. Hence, assign the responsibility to each person.

3. Decide the names for the files

Decide standard names for each file so that the user can easily search the file, and he will be able to find out which data is there in that file. Hence you can save time.

4. Data collection

This step will be the essential step in this implementation process. To make critical business decisions, you need valid, real-time data. So collect crucial and necessary data from different sources.

5. Construct a dataset

Once you have collected data, you need to validate the dataset by comparing it with another source and re-arranging it for the following process.

6. Data processing

After completing data validation, convert the data set into one single data so that software can easily understand it.

For example, if you have fields representing the final product like the assembled product, finished product, output product, etc. Just merge them into a single lot, the final product using data processing.

7. Data analyzing

With the help of software, analyze the data to get a better result because computer programming examines data accuracy better than a human.

8. Documentation

Record all the previous steps and results in documents and save them with the proper name.

9. Share documents

Share all documents of the data management process with your team members to understand all the implementation steps, standards, and responsibilities.

10. Cooperation between departments

Cooperation and proper communication between departments are crucial to avoid redundancy if your organization is large.

So communicate your process with other departments that avoid uncertainty about the data management process between departments.

Advantages of Product Data Management

These are the well-known benefits of the PDM system.

- Optimize the profitability of the business by reducing the cost incurred on production.

- Minimize the errors and save the expenditure incurred on offsetting casualties and mishaps.

- Enhance the overall productivity of the company and minimize the cycle times.

- Precisely address all the requirements of the business.

- Creates an opportunity for better business decision-making

- Facilitate teamwork by allowing the global team to communicate with each other easily.

- Instantly extract the most precise and accurate data.

- Immediately tracks and manages all changes related to product data.

Product Data Management Software

We’ll be listing some of the well-known PDM software. We hope this list assists our readers in selecting the best appropriate PDM software for their business.

1. Upchain

Upchain software is a cloud-based Autodesk fusion 360 managed, best product data management software for businesses of all sizes. It makes managing your product data easy and helps you avoid any mistakes.

Key features

Upchain software offers an intuitive drag-and-drop interface for easy product management.

- Easily manage your product data with custom fields and filters.

- Get real-time updates on your products’ statuses and changes.

- Collaborate with your team in a secure environment.

- Easily integrates with CAD tools and other software

- Connects product development processes

Screenshots of Upchain

Likes

- It provides an excellent service for BOM and change management.

- You can easily customize the workflows

Dislikes

- The user interface is not so good.

- 3D modeling and assembling are complex to handle

- More improvement is needed in features like Change management, Bill of materials

- It crashes sometimes

- Advanced features are missing in 3D tool.

- Application stability and API interface need to be improved

- advanced surfacing options are missing

Supported industries

- Building design

- Infrastructure

- Construction

Other details

More about Upchain

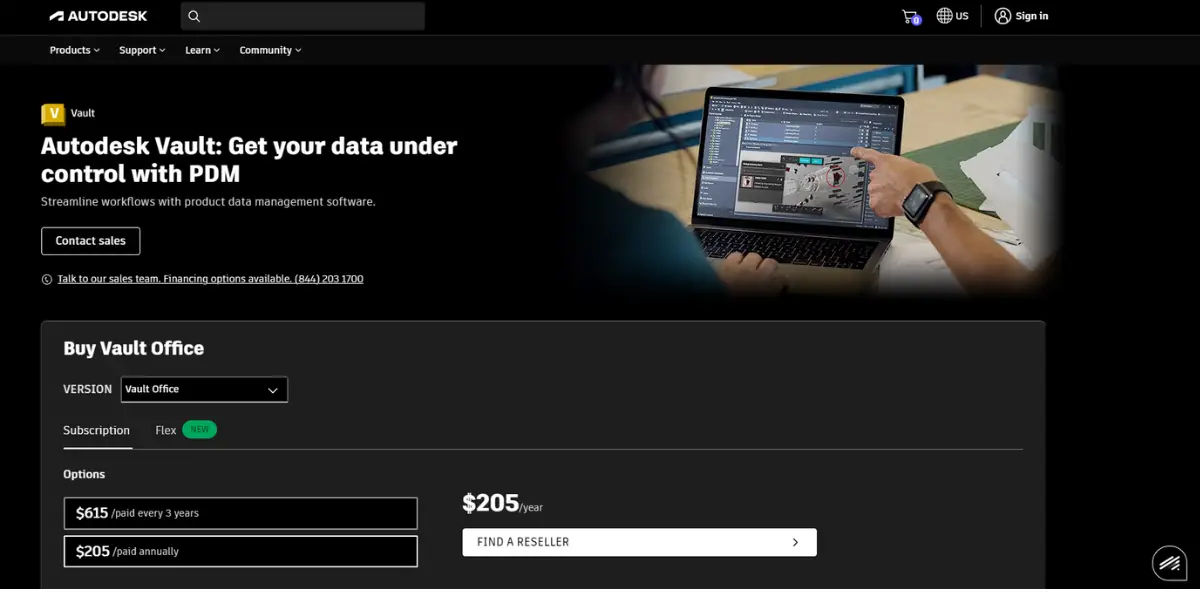

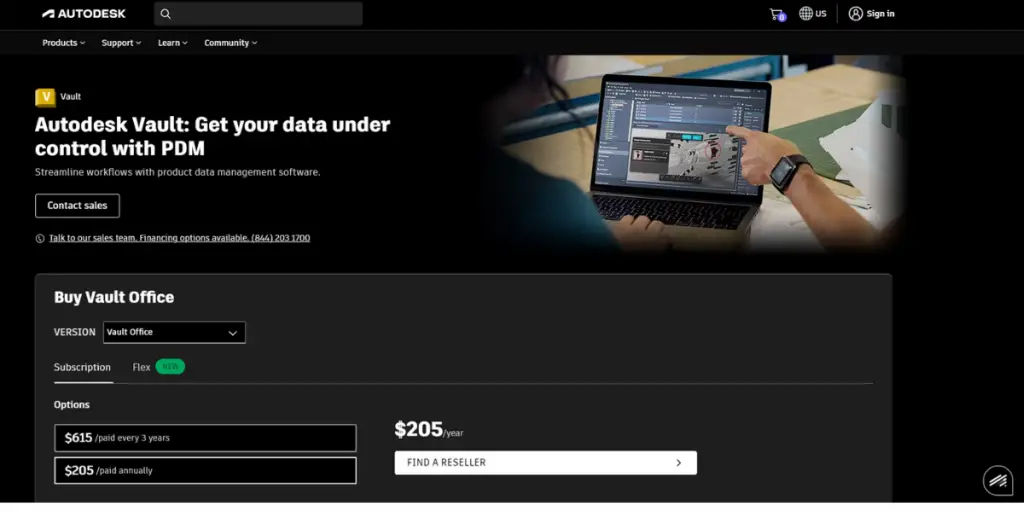

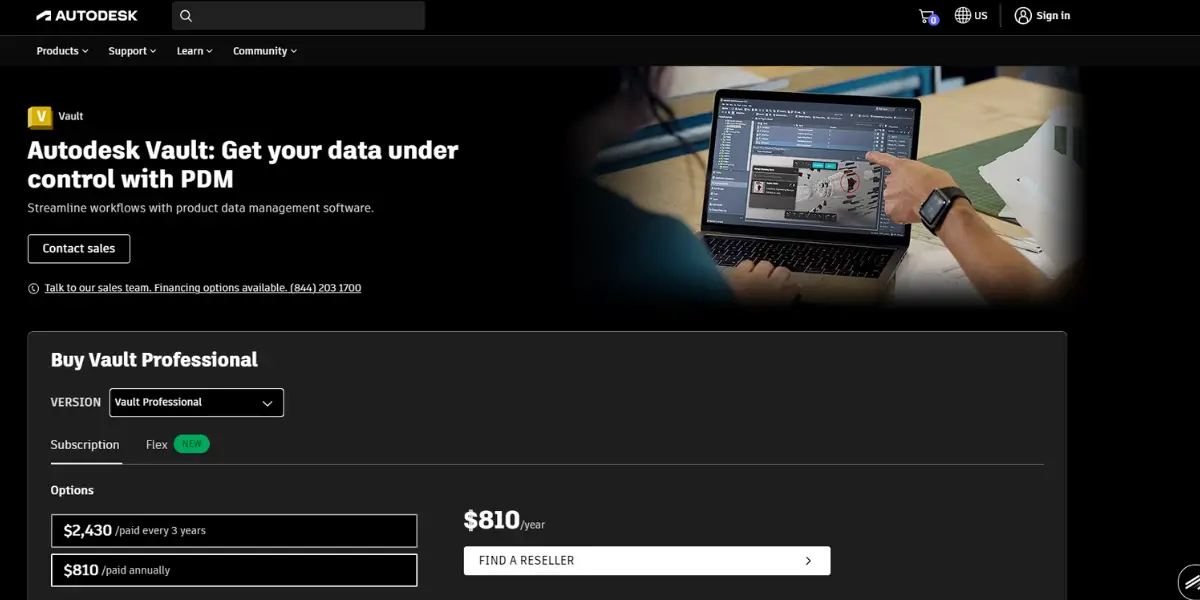

2. Autodesk Vault

Autodesk Vault is a product data management software developed by Autodesk. It offers an intuitive drag-and-drop interface and connects product development processes for easy product management.

Key features

- Integration with CAD

- Automated design and data reuse

- Concurrent design and scalability

- Accurate and comprehensive BOM

- Integrates PDM with ERP and PLM

- Store and manage product data securely

- Access product data from any location

- Create and share product data with others

Screenshots of Autodesk Vault

Likes

- You can quickly search and reuse design data

- Reduces errors with automation and data accessibility

Dislikes

- Unable to accommodate more than one person at a time on a file

- Gets sluggish on high load

- Issues with storage and backup

- Difficulty in learning for beginners

- Constant uploading issue

- Difficulty in import or export bulk capabilities

Supported industries

- Building design

- Infrastructure

- Construction

Other details

More about Autodesk Vault

3. Solidworks PDM

Solidworks PDM is an excellent product data management software for businesses of all sizes. It is easy to use and helps to keep product data secure and accessible from any location.

It also allows users to create and share product data with others, making collaborating on projects much more accessible.

Key features

- Centralizes product data in a secure, reliable system.

- Automate routine tasks and improve workflows.

- Easily share data with stakeholders across the organization.

- Manages data files and documentation.

- Allows to store design data securely and retrieve it easily.

- Collects data from multiple locations.

Screenshots of Solidworks PDM

SolidWorks Enterprise PDM generally comes with the following features and functionalities.

- Bill of Materials Management

- Product Development Lifecycle Management

- Version Control

- Formula Management

- Document Management

- Product Analytics

- Testing Management

Likes

- Aids in design and real-time simulations

- User-friendly software

- Speedy renderings

Dislikes

- Software is expensive with high system requirements

- Mobile version is slack

- Integration issues with Sharepoint or one drive for data

- Issues with large assemblies management needs improvement

Supported industries

- Aerospace and defense

- Architecture and construction

- Infrastructure

- Governments

- Home & lifestyle

- Transport & mobility

Other details

More about Solidworks PDM

4. Siemens Teamcenter

Siemens Teamcenter software is one of the best product data management software options. It offers many features and capabilities to help businesses manage their product data more effectively.

Key features

- BOM management

- Change management

- Document management

- Electrical design management

- Product cost management

Likes

- Helps to deliver large products with enhanced productivity.

- Easily integrates with other CAD solutions.

- Revision and data management

- Efficient workflows

- It offers industry-based solutions like Aerospace & Defense and Energy.

Dislikes

- Manufacturing Process Planning is complex

- User Experience Improvements

- Visualization and data loading on UI needs to improve

- Migration issues

- Error management

- Usability

- Customizing options are less

- Deployment issues

- Expensive upgrading

- No documentation and training manual support

Supported industries

- Aerospace and defense

- Automotive transportation

- Consumer product

- Electronics

- Energy and utilities

- Heavy equipment

- Insurance and financial

- Media and telecommunication

More about Siemens Teamcenter

5. OpenBOM

OpenBOM is a comprehensive product data management software that helps businesses manage their product data more effectively.

OpenBOM provides users with a centralized repository for storing and managing product data. It also offers a variety of tools for managing parts, purchases, CAD files, and documents.

Key features

- BOM management

- Item management

- Change management

- CAD integration

Screenshots of OpenBOM

Likes

- Efficient sharing of BOM with other company

- 3D viewer for preview of images and parts

- Allows multiple simultaneous edit and data sharing

- Effortless integrations

Dislikes

- Engineering change requests feature needs to be improved

- Cannot handle large and complex BOMs

- Issues with speed and no offline access

- User interface is not intuitive

- Occasional bugs

More about OpenBOM

6. Delogue

Delogue is a top product lifecycle management software that helps businesses manage their product data more efficiently.

Delogue is specifically designed for the lifestyle industry and can adequately address all the requirements of this specific industry.

Delogue accumulates all the product data, appropriately manages the project, and consistently communicates with your development team during the lifecycle workflow.

To enhance accuracy, efficiency, and knowledge accessibility, Delogue stored all the sensitive information in one central place. As a result, Delogue is a valuable tool to boost the productivity of your production team.

Delogue can be easily incorporated into your current ERP system, apart from these peculiar functionalities.

Key features

- Manage product data and specifications more efficiently

- Keep track of products, manage information, and collaborate with team members effectively.

- Streamline your workflow for faster product development

- Get real-time feedback from your team and customer

Likes

- Easy access to information

- Decent user interface

- Enables easy design changes to the final product

Dislikes

- Errors made while commenting cannot be deleted

- You can’t see whether your supplier opened the message or the email sent to him

- Complexity of platform

Other details

More about Delogue

7. Altium 365

Altium 365 revolutionizes the product design process with its comprehensive platform that connects PCB design, MCAD, data management, and collaboration – streamlining workflows to make electronics engineering easier.

Feature

- PCM design

- Mechanical and electronic collaboration

- Centralized cloud storage

- Life cycle management and libraries

- Keeps team working together

- Manufacturing with convenient version-control

Screenshots of Altium 365

Likes

- Easy to use

- Good customer support

- Share the PCB information with customers and suppliers

- Easy integration with mechanical CAD

- Collaboration and online libraries for team sharing

- Active BOM

- New and improved homepage

- Revision control of symbol, footprint, and unified component released to the server

Dislikes

- Expensive

- Newly released features have some bugs

- Frequently crashes

- Poor design rule management

- BOM and the 3D view are a bit slow

- Need improvement in Elbow position option

- SVN and GIT migration does not work well

- Complexity

Other details

8. Synergis Adept

Synergis Adept is unified control of your engineering drawings and business documents in one secure place. You no longer need to search multiple locations for the information needed – access it through a shared collaboration platform.

Features

- Single source of truth

- Powerful engineering document management software

- Efficient workflow, collaboration, and transmittals

- Integrated with AutoCAD, Solidworks, Inventor, MicroStation

- Design visualization

- Security and Control

- Easy to connect applications and eliminate information silos

Screenshots of Synergis Adept

Likes

- Simple platform

- Easy to setup and learn

- Helps find, manage, share, and integrate engineering and enterprise information

- Good customer support

- Storage of backup files and sharing

- Seamless workflow

Dislikes

- Poor document management

- Some users feel that there is a lack of customization and modernization while using the modern web 2.0 world.

- Lagging while working with a large number of drawings

- Expensive for smaller enterprises

- Issues with newer versions

Supported industries

- Chemical

- Energy and utilities

- Manufacturing

- Mining

- Oil and gas

- Facilities and building

Other details

9. Onshape

Onshape’s cloud-based PDM system empowers product developers with the resources to rapidly create, collaborate and bring products quickly from concept to market.

Feature

- Cloud-native Computer-Aided Design(CAD)

- Provides a multi-user environment

- Flexible pricing plans

- Built-in Product data management with 3D CAD

- Agile product development

- It offers powerful automation and customization tool.

Screenshots of Onshape

Likes

- Easy-to-use and user-friendly UI

- Easy learning management features

- No need for hardware for the server

- Easy and smooth development of product

Dislikes

- Difficult to use large-scale architectural projects

- Some users faced occasional glitches and clashes in large-scale projects

- Need improvement in the sheet metal side of modeling and documentation

- Less functionality compare to more mature CAD software

- No axis for creating revolve shapes

Supported industries

- Automotive

- Consumer products

- Education

- Electronics

- Industrial equipment

- Medical

Other details

10. Windchill PDM

Windchill PLM software offers extraordinary value with its easy-to-implement PDM and PLM tools suite. No need to start from scratch; users can reap the rewards quickly, right out of the box.

Features

- Open architecture for PDM and PLM

- Easy integration with other systems

- Real-time information sharing

- Dynamic data visualization

- Easy, secure data access

- Quality focused process

- Geographically distributed teams

Screenshots of Windchill PDM

Likes

- Rich application and intuitive product structure management software

- Version control and powerful configuration management

- Comprehensive security measures

- Action icons of files are easy to recognize

- Preview UI file is very useful

- Upgraded architecture

- Effective collaboration tools

- Compatibility with multiple devices

- Easy to find any part and assembly with its drawing file

Dislikes

- Steep learning curve to fully utilize the platform

- Some reference errors are difficult to solve

- Some users felt speed is less

- Not designed for process manufacturers.

- Not suited for enterprises with less than 5 users

- Library module needs improvement with better standard parts

- Issues with handling backup files after a gap

Other details

Uses of PDM software

- It helps to access the design files from CAD software. Generally, it is not easy to find these design files.

- It helps to reduce development costs and errors.

- It allows you more visibility across teams and improves cooperation between team members.

- It helps the organization to get complete control over the product information.

- It helps to get efficient output from the design and engineering team.

- It allows the design team to speed up the designing process and helps release the product quickly in the market.

FAQs

Conclusion

The centralized Product Data Management system serves as a crucial hub for efficient control of both product data and manufacturing processes.

Implementing PDM software not only empowers the engineering team but also results in significant time and resource savings.

We trust that this blog post has equipped you with valuable insights into the diverse platforms available, assisting you in making well-informed decisions tailored to your needs.

Reference

- Documentation of Synergis Adept- Camparion report

- Documentation of Altium 365